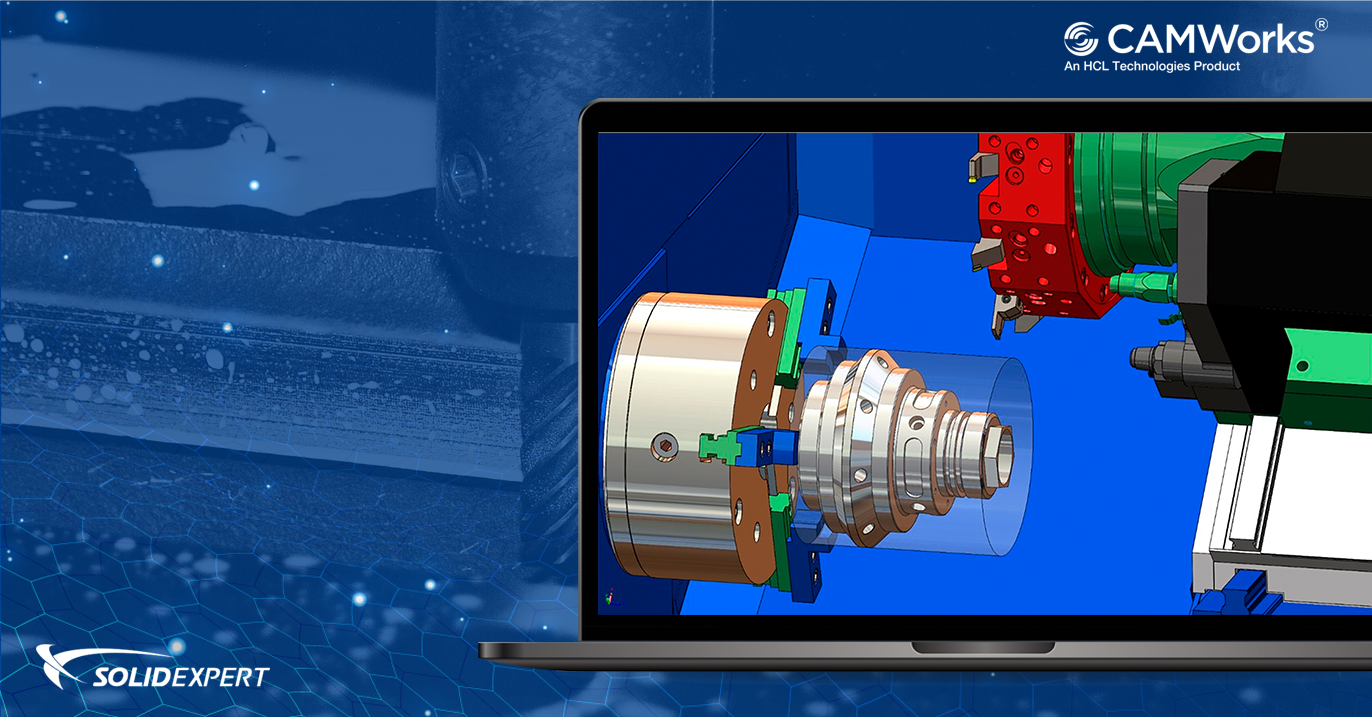

Increased automation in CNC programming: Adding 39 APIs to the current suite helps reduce repetitive activities and provides a solid foundation for shops that want to customize or automate their systems to accelerate CNC programming output. Particularly beneficial in mill-turn operations is the selection of turn profiles by specifying the angle at which the profile has to be extracted. This first in the feature-based machining world makes program changes very quick and efficient. Turn feature definition enhancement: Turn profiles are now fully associated with the model they are extracted from, making them fully associative to the sketches. This reduces data redundancy and saves valuable shop floor time (see Figure 1).ĭemonstration of how CAMWorks 2014 Makes Significant Progress On Using WIP STL Models.Īlong with support for SolidWorks® 2014, CAMWorks 2014 accelerates design-to-part time by improving the productivity of CNC programmers with the addition of a number of enhancements, including: With the addition of true G-code simulation, CAMWorks is the most complete fully integrated end-to-end CAD/CAM solution, from the initial part design to creating a CNC program to full machine simulation. (Scottsdale, AZ) offers their CAMWorks® 2014 intuitive solids-based CNC programming solution. To help shops stay informed and maintain their edge in machining capabilities, here are some of the latest advances in CAD/CAM applications. In part design, CAD/CAM integrates FEA capabilities to test and predict how certain materials machined on a prototype will perform before anything is actually built. In quality assurance, CAD/CAM is moving deeper into the footprint of part inspection and surface finish measurement. Shops are hard pressed to keep up with all of the competitive advances in machining alone, where each day introduces a new toolpath creation, a new simulation of multitask machining on a part, a new program that performs more simultaneous operations than ever before in one machine setup – all accessible and monitored from anywhere through new mobile applications.

Lubricants, Coolants, Metalworking Fluidsįaster multicore and embedded processors are combining with cloud-based innovations to increase the capabilities and expand the boundaries of CAD/CAM software far beyond the origins of its traditional work envelope.Computerized Maintenance Management Systems.

Abrasives, Belts, Brushes, Grinding Wheels.

0 kommentar(er)

0 kommentar(er)